Introduction

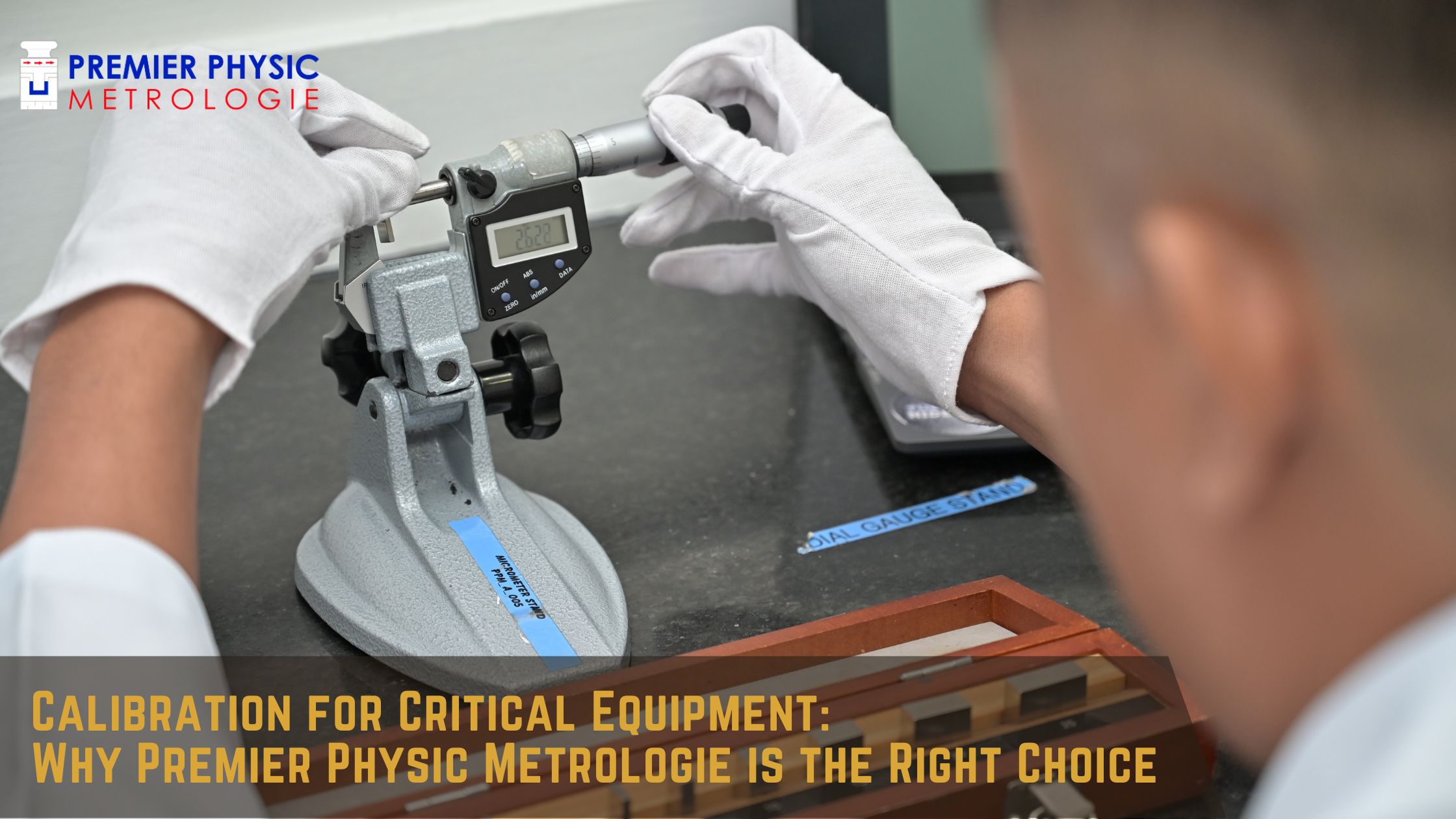

In today’s competitive industrial landscape, ensuring the accuracy of equipment is essential for maintaining product quality, operational efficiency, and regulatory compliance. Calibration plays a pivotal role in this process, particularly for industries that depend on precise measurements to uphold safety and quality standards, such as pharmaceuticals, manufacturing, food processing, and electronics. In the Philippines, Premier Physic Metrologie has become the trusted choice for calibration services, known for its dedication to precision, expertise, and client satisfaction.

This article explores the importance of calibration for critical equipment, the unique advantages of working with Premier Physic Metrologie, and why accurate calibration is essential for meeting industry standards, reducing risks, and enhancing operational efficiency.

Understanding the Importance of Calibration for Critical Equipment

Calibration is the process of verifying and adjusting the accuracy of measurement instruments to ensure they produce precise readings. For industries that rely on exact measurements, such as manufacturing or pharmaceuticals, calibration is critical. Properly calibrated equipment ensures that measurements are accurate, reducing the risk of errors that can impact product quality, safety, and compliance.

Calibration of critical equipment brings several key benefits, including:

- Enhanced Product Quality: Accurate measurements are essential for producing products that meet quality standards, reducing the chance of defects or inconsistencies.

- Compliance with Industry Standards: Many industries, including pharmaceuticals and food processing, must comply with strict regulatory requirements. Calibration ensures adherence to these standards.

- Operational Efficiency: With calibrated equipment, operations are more efficient, reducing the likelihood of disruptions caused by inaccurate readings.

- Cost Savings: By reducing product waste and minimizing the need for rework, calibration helps companies save money in the long run.

Key Industries Where Calibration is Essential

Calibration is especially important in industries where accuracy is critical, such as:

- Pharmaceuticals: Ensures the correct dosage in medicines and maintains sterility.

- Manufacturing: Enhances product quality and consistency, particularly in high-precision production.

- Food and Beverage: Ensures that food safety standards are met by maintaining temperature, humidity, and other critical factors.

- Electronics: Ensures components function correctly and prolongs the life of sensitive equipment.

Why Choose Premier Physic Metrologie for Calibration Services?

Premier Physic Metrologie stands out in the calibration industry in the Philippines due to its exceptional service, commitment to accuracy, and specialized solutions tailored to meet the needs of various sectors. Here are some reasons why Premier Physic Metrologie is the preferred choice:

1. ISO-Certified Calibration Services

Premier Physic Metrologie holds ISO certifications, such as ISO 17025, demonstrating their commitment to international quality and competence standards. These certifications assure clients that Premier Physic Metrologie follows strict calibration protocols, ensuring accurate, consistent results that meet global standards.

- Quality Assurance: Premier Physic Metrologie’s ISO-certified services guarantee precision and reliability.

- Documentation: Detailed calibration reports are provided to meet audit requirements, simplifying compliance for industries that need to demonstrate regulatory adherence.

2. Experienced Team of Calibration Experts

The expertise of Premier Physic Metrologie’s team is one of its greatest assets. With years of experience in calibration, the team brings valuable industry knowledge, ensuring each piece of equipment is calibrated to the highest standards. Their expertise extends across various fields, enabling them to provide specialized services tailored to each client’s industry.

3. Comprehensive Range of Calibration Services

Premier Physic Metrologie offers a broad spectrum of calibration services, from temperature and humidity control to pressure, electrical, and dimensional calibration. This versatility makes them a one-stop provider for industries with diverse calibration needs.

- Temperature and Humidity Calibration: Essential for industries like food and pharmaceuticals.

- Pressure and Vacuum Calibration: Critical for equipment in industrial manufacturing and HVAC systems.

- Electrical Calibration: For companies in electronics and other precision-dependent sectors.

4. State-of-the-Art Equipment and Facilities

Premier Physic Metrologie’s facilities are equipped with advanced calibration tools and technology. This investment in cutting-edge equipment allows them to deliver highly accurate results and meet the growing demands of industries with strict calibration needs.

5. Commitment to Sustainability

Premier Physic Metrologie is committed to eco-friendly practices. By extending the lifespan of calibrated equipment and helping companies avoid waste due to inaccuracies, they contribute to sustainability. This aligns with the growing demand from businesses in the Philippines for environmentally responsible service providers.

6. Nationwide Reach and Client Support

Premier Physic Metrologie provides calibration services across the Philippines, ensuring that even companies in remote locations can access high-quality calibration. Their customer service and support are designed to address client needs promptly, making them a reliable partner.

The Calibration Process at Premier Physic Metrologie

The calibration process involves several steps to ensure each instrument is thoroughly examined, adjusted, and documented:

Step 1: Pre-Calibration Assessment

Before calibration, Premier Physic Metrologie’s technicians assess the equipment’s condition and verify the client’s specific requirements. This preliminary step ensures that the calibration is tailored to meet operational needs and compliance standards.

Step 2: Calibration Procedures

Using specialized equipment, technicians perform calibration according to strict standards, adjusting and verifying the accuracy of each instrument. Each measurement is tested to ensure it meets the required precision.

Step 3: Documentation and Reporting

After calibration, detailed reports are provided, documenting the calibration process, results, and any adjustments made. These reports help clients meet compliance requirements and provide essential records for audits.

Step 4: Post-Calibration Support

Premier Physic Metrologie offers support to help clients understand their calibration results and maintain their equipment’s accuracy. This includes guidance on calibration schedules, adjustments, and any necessary follow-up.

Benefits of Regular Calibration with Premier Physic Metrologie

Regular calibration offers numerous benefits, particularly when done by a trusted provider like Premier Physic Metrologie:

1. Reduces Downtime and Increases Equipment Longevity

Calibrated equipment experiences fewer errors, reducing downtime and increasing its lifespan. Premier Physic Metrologie’s services help prevent costly interruptions due to inaccurate measurements.

2. Increases Confidence in Measurement Accuracy

Accurate measurements are essential for product quality and regulatory compliance. Premier Physic Metrologie’s meticulous calibration methods ensure clients can trust their equipment.

3. Ensures Compliance and Avoids Penalties

Industries that fail to meet calibration standards risk fines and penalties. Premier Physic Metrologie’s services help companies maintain compliance, protecting them from regulatory issues.

4. Improves Overall Product Quality

With precise calibration, companies can improve product quality, ensuring customer satisfaction and reducing the risk of recalls.

The Role of Calibration in Meeting Industry Standards

Calibration is crucial for meeting various industry standards, which vary by sector but generally include ISO, FDA, and local regulatory requirements. By partnering with Premier Physic Metrologie, companies in the Philippines can rest assured their calibration needs meet these standards, enhancing their market competitiveness.

Pharmaceutical Compliance: Ensuring Patient Safety

For pharmaceutical companies, precise calibration is necessary for drug safety. Calibration ensures that measurements for temperature, humidity, and pressure meet FDA and ISO standards, critical for patient safety and compliance.

Food Industry Standards: Meeting ISO 22000

In the food industry, ISO 22000 standards require precise environmental control to prevent contamination. Premier Physic Metrologie’s calibration services ensure that temperature and humidity monitoring systems function accurately, preserving product safety.

Manufacturing: Adhering to Quality Management Standards

For manufacturing companies, ISO 9001 compliance is essential. Accurate calibration helps maintain product quality and adherence to quality management standards, essential for customer satisfaction and brand reputation.

Why Regular Calibration is Essential for Risk Management

Calibration is not just about accuracy—it’s also about managing risks. Uncalibrated or poorly calibrated equipment can lead to a series of costly problems:

- Financial Losses Due to Product Waste: Errors in measurement can result in defective products, causing financial losses and product recalls.

- Operational Disruptions: Inaccurate equipment can disrupt operations, leading to delays and increased maintenance costs.

- Health and Safety Risks: In industries like food and pharmaceuticals, inaccurate measurements can pose health and safety risks for consumers.

Regular calibration with Premier Physic Metrologie mitigates these risks, providing confidence that equipment will operate correctly and measurements will be accurate.

Conclusion

Calibration is fundamental to the success and safety of many industries in the Philippines. For companies that prioritize accuracy, efficiency, and compliance, Premier Physic Metrologie offers reliable, high-quality calibration services that support these objectives. With an ISO-certified team, state-of-the-art facilities, and a commitment to sustainability, Premier Physic Metrologie stands out as the premier choice for calibration services.

Whether it’s for pharmaceuticals, food processing, manufacturing, or electronics, Premier Physic Metrologie provides tailored calibration solutions that help companies meet industry standards, reduce operational risks, and enhance product quality. By partnering with Premier Physic Metrologie, Filipino businesses can ensure their equipment is accurately calibrated, compliant, and ready to meet the demands of a competitive market.