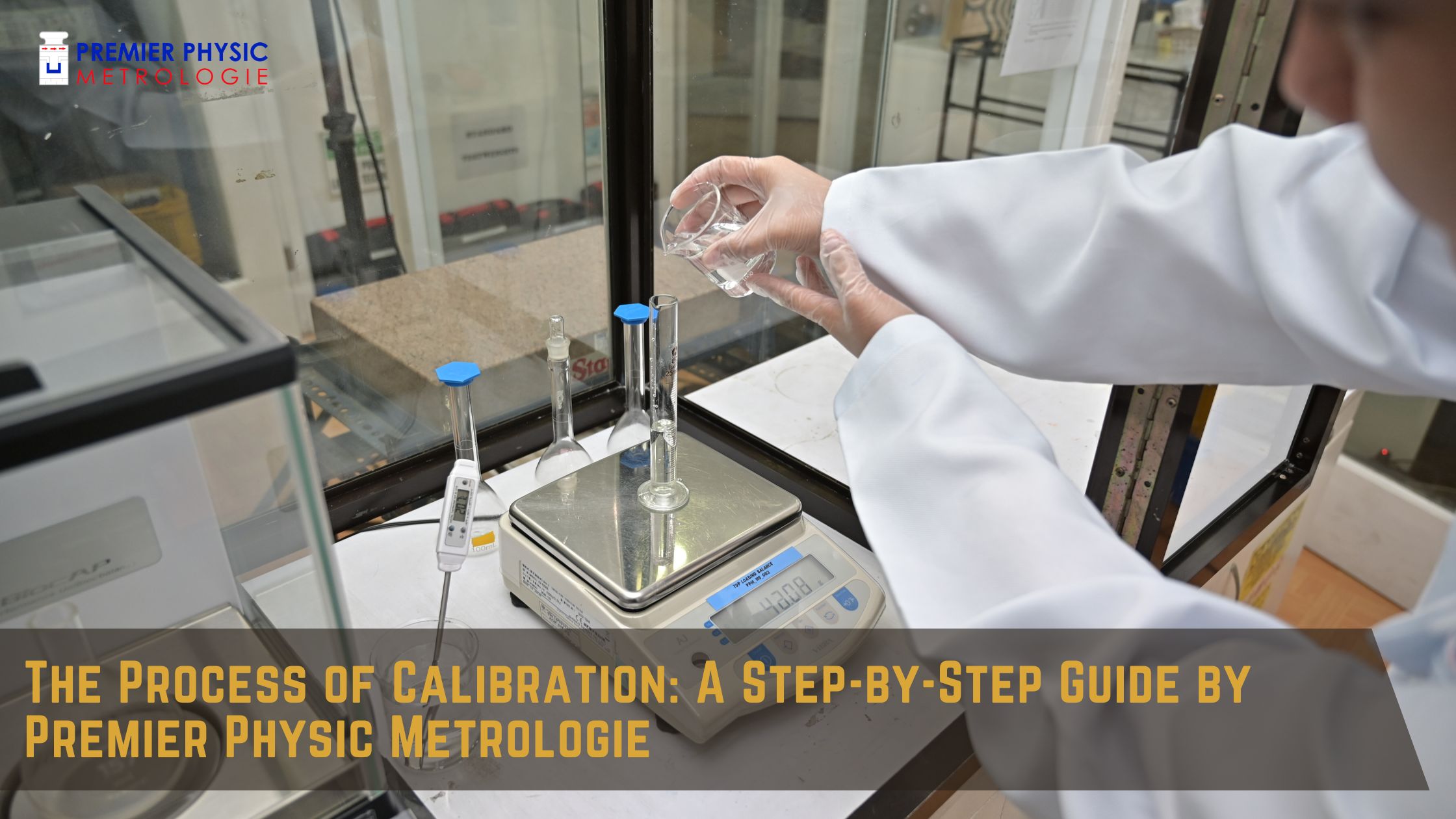

Introduction

Calibration is an essential process in various industries to ensure the accuracy and reliability of measuring instruments. It involves comparing the measurements of a device under test with a standard known value and adjusting the device to match the standard. This guide by Premier Physic Metrologie will take you through the entire calibration process, explaining each step in detail and highlighting its importance.

What is Calibration?

Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range. Eliminating or minimizing factors that cause inaccurate measurements is critical in maintaining the quality and accuracy of instruments.

Importance of Calibration

Calibration is crucial in industries such as manufacturing, healthcare, and aerospace, where precision is paramount. Regular calibration ensures compliance with international standards, enhances product quality, and increases customer trust.

Types and Categories of Calibration

Calibration can be categorized based on the type of instrument and the parameters being measured. Here are some common types:

Electrical Calibration

Electrical calibration involves calibrating electrical instruments like multimeters, oscilloscopes, and power supplies. It ensures that these instruments provide accurate voltage, current, and resistance measurements.

Mechanical Calibration

This type involves calibrating devices like micrometers, calipers, and torque wrenches. It ensures the accuracy of physical measurements such as length, width, and torque.

Thermal Calibration

Thermal calibration is performed on temperature measuring devices such as thermocouples, RTDs, and thermometers. It ensures these devices provide accurate temperature readings.

Pressure Calibration

Pressure calibration involves calibrating devices that measure pressure, such as barometers, manometers, and pressure gauges. It ensures accurate pressure measurements.

Flow Calibration

Flow calibration is performed on instruments that measure the flow rate of liquids or gases, like flow meters. It ensures accurate flow measurement.

Symptoms and Signs of Calibration Issues

Inaccurate Readings

One of the most common signs of calibration issues is inconsistent or inaccurate readings from measuring instruments. This can lead to errors in the final product or process.

Frequent Adjustments

If an instrument requires frequent adjustments to maintain accuracy, it might be a sign that it needs recalibration.

Deviations in Test Results

Unexpected deviations in test results can indicate that the instrument is out of calibration and needs attention.

Unusual Instrument Behavior

Instruments that behave erratically or exhibit unusual readings are likely in need of calibration.

Causes and Risk Factors

Environmental Factors

Temperature, humidity, and other environmental conditions can affect the accuracy of measuring instruments, leading to the need for recalibration.

Mechanical Wear and Tear

Regular use can cause wear and tear on instruments, affecting their accuracy and necessitating recalibration.

Electrical Interference

Electrical noise and interference can impact the performance of electronic measuring instruments, requiring calibration to maintain accuracy.

Improper Handling

Improper handling or storage of instruments can lead to calibration issues, as it may cause physical damage or environmental exposure.

Diagnosis and Tests

Initial Inspection

Before calibration, a thorough inspection of the instrument is necessary to identify any obvious issues or damages.

Performance Testing

Performance testing involves checking the instrument against known standards to assess its accuracy.

Comparative Analysis

Comparing the instrument’s readings with those of a calibrated standard helps determine the extent of deviation and the need for adjustment.

Treatment Options

In-House Calibration

Some organizations have the capability to perform in-house calibration using their own standards and procedures.

Third-Party Calibration

Many organizations opt for third-party calibration services to ensure unbiased and accurate calibration of their instruments.

Manufacturer Calibration

Returning the instrument to the manufacturer for calibration ensures it is calibrated according to the original specifications.

Preventive Measures

Regular Calibration Schedule

Establishing a regular calibration schedule helps maintain the accuracy and reliability of instruments.

Proper Storage

Proper storage of instruments in controlled environments can minimize the need for frequent recalibration.

Training and Awareness

Training personnel on the proper handling and use of instruments can reduce calibration issues caused by improper handling.

Environmental Controls

Implementing environmental controls such as temperature and humidity regulation can help maintain instrument accuracy.

Actual Application

In Manufacturing Plant

A manufacturing plant experienced frequent product defects due to inaccurate measurements from their calipers. Implementing a regular calibration schedule significantly reduced defects and improved product quality.

In Healthcare Facility

A healthcare facility noticed discrepancies in patient test results. After recalibrating their diagnostic equipment, the accuracy of test results improved, enhancing patient care.

Expert Insights

Quote from Calibration Expert

“Regular calibration is not just a regulatory requirement; it is a fundamental practice to ensure the accuracy and reliability of measurements, which ultimately impacts product quality and safety.” – John Smith, Calibration Specialist.

Industry Best Practices

Adopting industry best practices for calibration can help organizations maintain the highest standards of accuracy and reliability.

Why Choose Premier Physic Metrologie for Calibration Services in the Philippines

Premier Physic Metrologie (PPM) has been a trusted name in calibration services for over two decades, consistently delivering excellence and innovation. Our unwavering commitment to quality and environmental sustainability sets us apart in the industry. Here’s why PPM excels in calibration services in the Philippines:

Expertise and Experience

With 20 years of experience, PPM has developed unparalleled expertise in calibration services. Our seasoned professionals are equipped with the knowledge and skills necessary to ensure precise and reliable calibration for a wide range of instruments. This extensive experience enables us to provide tailored solutions that meet the unique needs of each client, ensuring optimal performance and compliance with industry standards.

ISO/IEC 17025:2017 Accreditation

PPM is proud to be an ISO/IEC 17025:2017 accredited calibration laboratory. This prestigious accreditation reflects our commitment to maintaining the highest standards of quality and competence in our calibration services. It assures our clients that our procedures are rigorously evaluated and meet international standards, providing them with the confidence that their instruments are calibrated to the highest level of precision.

Cutting-Edge Technology

At PPM, we leverage the latest technology to deliver top-notch calibration services. Our state-of-the-art laboratories are equipped with advanced tools and equipment, allowing us to perform highly accurate and efficient calibrations. By staying at the forefront of technological advancements, we ensure that our clients benefit from the most current and reliable calibration methods available.

Commitment to Sustainability

One of our core goals at PPM is reducing carbon footprints through calibration. We understand the critical role that calibration plays in minimizing environmental impact. Properly calibrated instruments operate more efficiently, reducing waste and energy consumption. By choosing PPM, you are partnering with a company that prioritizes environmental responsibility and actively contributes to a more sustainable future.

Comprehensive Services

PPM offers a comprehensive range of calibration services, catering to various industries and applications. From industrial instruments to precision laboratory equipment, we have the capability to handle diverse calibration needs. Our comprehensive service offerings ensure that our clients can rely on us as a one-stop solution for all their calibration requirements.

Unmatched Customer Support

Customer satisfaction is at the heart of our operations. We pride ourselves on delivering exceptional customer support and building long-term relationships with our clients. Our dedicated team is always ready to assist with any queries or concerns, providing prompt and effective solutions to ensure your instruments remain in peak condition.

Proven Track Record

Our extensive client portfolio and numerous success stories speak volumes about our reliability and excellence in calibration services. Businesses across the Philippines trust PPM for our consistent performance, accuracy, and professionalism.

In conclusion, Premier Physic Metrologie stands out as the premier choice for calibration services in the Philippines. Our rich experience, ISO/IEC 17025:2017 accreditation, advanced technology, sustainability efforts, comprehensive services, outstanding customer support, and proven track record make us the ideal partner for all your calibration needs. Choose PPM to ensure precision, efficiency, and a greener future.

Conclusion

Calibration is a vital process that ensures the accuracy and reliability of measuring instruments across various industries. By understanding the types, symptoms, causes, and preventive measures, organizations can maintain high standards of quality and compliance. Regular calibration not only improves product quality but also enhances customer trust and operational efficiency.